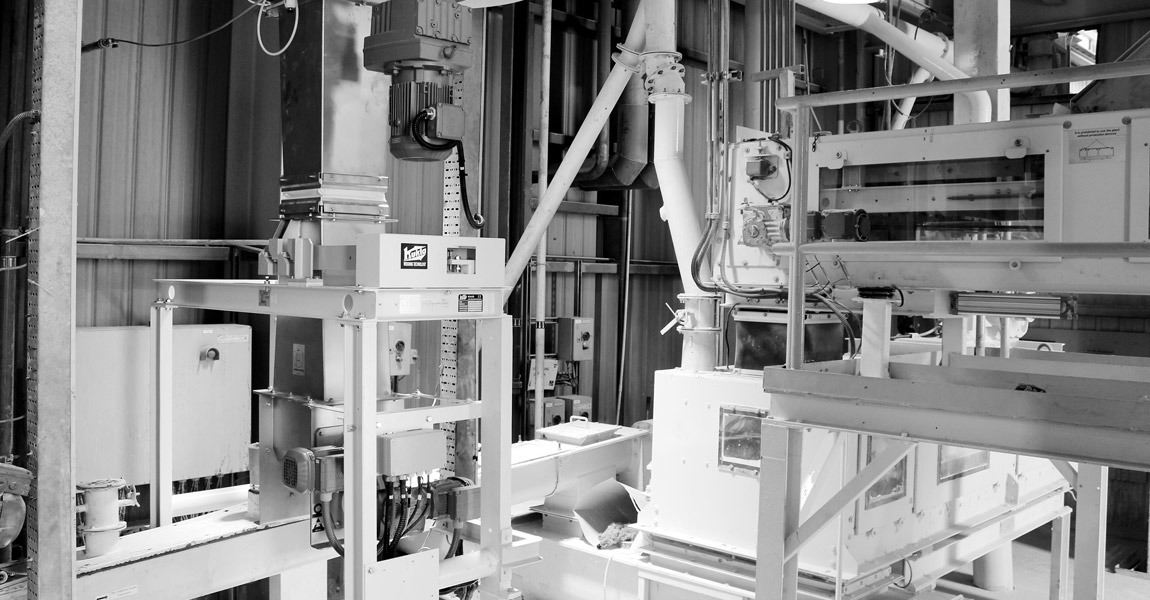

Loss-In-Weight-Feeders

for high-precision dosing of additives

Loss-in-weight-feeders combine the accuracy of a static measuring with the flexibility and efficiency of a continuous dosing system. Due to the flexible construction of the KUKLA-loss-in-weight-feeder strongly flowing and extremely heavily flowing materials can be dosed exactly. By means of loosening devices, which work asynchronously to the actual dosing system, the product is supplied to the dosing screw in a material-friendly and precise way.

Loss-In-Weight-Feeder D-DW-1

for high-precise dosing of additives, with dosing screw and speed-controlled drive

Technical Data:

Conveying material: dust like bulk materials

Conveying capacity: 10 kg/h – 2000 kg/h

Screw speed: depending on the set point and the belt load

Screw diameter: 20 mm – 140 mm

Bulk density: 300 kg/m³ – 2500 kg/m³

Granulation: dusty to fine-grained

Adjustment range: 1:10 (upgradeable up to 1:50 with feedback-encoder)

ATEX: versions available

Accuracy: ± 0,5 %

If required customized special solutions are available!

Depending on the set value and on the loss of weight within the weighing bin the speed revolution of the screw is controlled so that the dosing capacity corresponds exactly to the set value. KUKLA-loss-in-weight-feeders are mounted onto a solid steel frame in order to ensure the stability required for a high-precision measuring. Loss-in-weight-feeders can also be supplied according ATEX rules, on request.

Significant Benefits

• no influence on accuracy by tare alteration

• completely closed system

• versatilely applicable

• minimal maintenance works

Requirement

• stabile vibration-free subconstruction

Application Range:

-

Gypsum

-

Cement

-

Construction materials

-

Chemistry

-

Coal dust

-

Plastics

-

Food

-

Animal feed

-

Materials with high temperatures

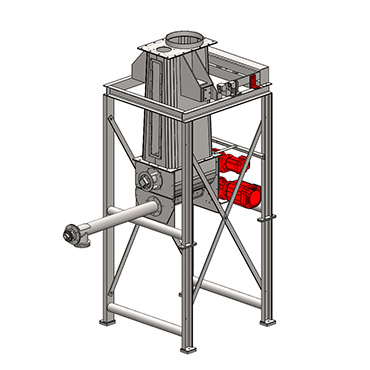

Loss-In-Weight-Feeder D-DW-2

for high-precise dosing of additives, with dosing screw and speed-controlled drive

Technical Data:

Conveying material: dust like bulk materials

Conveying capacity: 500 kg/h – 5000 kg/h

Screw speed: depending on the set point and the belt load

Screw diameter: 100 mm – 220 mm

Bulk density: 100 kg/m³ – 2500 kg/m³

Granulation: dusty to fine-grained

Adjustment range: 1:10 (upgradeable up to 1:50 with feedback-encoder)

ATEX: versions available

Accuracy: ± 0,5 %

If required customized special solutions are available!

Depending on the set value and on the loss of weight within the weighing bin the speed revolution of the screw is controlled so that the dosing capacity corresponds exactly to the set value. KUKLA-loss-in-weight-feeders are mounted onto a solid steel frame in order to ensure the stability required for a high-precise measuring. Loss-in-weight-feeders can also be supplied according ATEX rules, on request.

Significant Benefits

• no influence on accuracy by tare alteration

• completely closed system

• versatilely applicable

• minimal maintenance works

Requirement

• stabile vibration-free subconstruction

Application Range:

-

Gypsum

-

Cement

-

Construction materials

-

Chemistry

-

Coal dust

-

Plastics

-

Food

-

Animal feed

-

Materials with high temperatures

Loss-In-Weight-Feeders D-DW-3

for high-precise dosing of additives, with dosing screw and speed-controlled drive

Technical Data:

Conveying material: dust like bulk materials

Conveying capacity: 1000 kg/h – 10000 kg/h

Screw speed: depending on the set point and the belt load

Screw diameter: 150 mm – 420 mm

Bulk density: 100 kg/m³ – 2500 kg/m³

Granulation: dusty to fine-grained

Adjustment range: 1:10 (upgradeable up to 1:50 with feedback-encoder)

ATEX: versions available

Pressure shock resistant: up to 6 bar

Accuracy: ± 0,5 %

If required customized special solutions are available!

Depending on the set value and on the loss of weight within the weighing bin the speed revolution of the screw is controlled so that the dosing capacity corresponds exactly to the set value. KUKLA-loss-in-weight-feeders are mounted onto a solid steel frame in order to ensure the stability required for a high-precise measuring. Loss-in-weight-feeders can also be supplied according ATEX rules and in pressure shock proof design, on request.

Significant Benefits

• no influence on accuracy by tare alteration

• completely closed system

• versatilely applicable

• minimal maintenance works

Requirement

• stabile vibration-free subconstruction

Application Range:

-

Gypsum

-

Cement

-

Construction materials

-

Chemistry

-

Coal dust

-

Plastics

-

Food

-

Animal feed

-

Materials with high temperatures

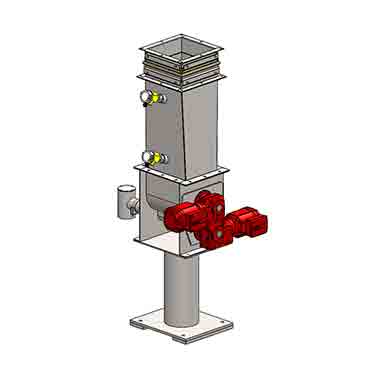

Volumetric Dosing Device V-DG

for volumetric dosing of additives

Technical Data:

Conveying material: dust like bulk materials (additives)

Conveying capacity: 10 kg/h – 5000 kg/h

Screw speed: depending on the set point

Screw diameter: 20 mm – 200 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to fine-grained

Adjustment range: 1:10

ATEX: versions available

If required customized special solutions are available!

A volumetric dosing device is extremely versatile. The classical area of application is within the low to middle range of conveying capacity for continuous dosing of fine to granulated bulk materials. Volumetric dosing devices are applied especially for dosing of additives in the gypsum board production.

Significant Benefits

• completely closed system

• versatile in use

• minimal maintenance works

Requirement

• stable vibration-free subconstruction

Application Range:

-

Gypsum

-

Cement

-

Construction materials

-

Chemistry

-

Animal feed

-

Materials with high temperatures