Single and Multiple Roller Belt Scales

for installation into existing conveying belt systems

Their main application is measuring and totalizing of bulk material flow. The measured values obtained can serve as control input for downstream process steps. The decision whether to apply a single roller belt scale (EBW-E-…-…) or a multiple roller belt scale (EBW-M-…-…) depends on the speed of the conveyor belt as well as on the required accuracy.

-

Belt width from 200 to 2800 mm

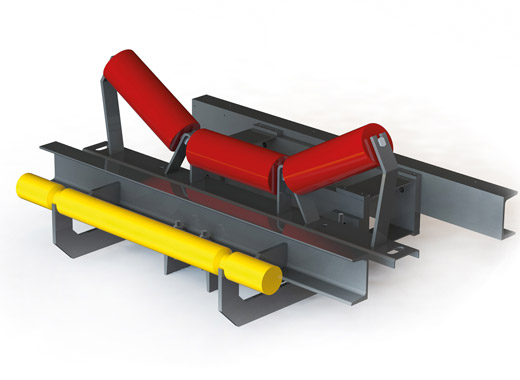

Single Roller Belt Scale EBW-E-C2

for installation into existing conveying belt systems

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 1,0 t/h up to 10000 t/h

Belt speed: 0,1 m/s up to 2 m/s

Belt width: 300 mm up to 2800 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to coarse-grained

Inclination conveyor belt: up to 20 degrees increasing or decreasing

ATEX: versions available

Accuracy: ± 1,0 %

If required customized special solutions are available!

Scales of the series EBW-E-C2 are suitable for installation into existing conveyor belt systems. They are used for measuring and totalizing of bulk material flow. For the weight measuring a modified roller station is mounted onto the single roller belt scale. For the speed measuring a digital tacho is provided which is either running on the return belt or attached to the tail pulley.

Optionally the scale can be equipped with a test weight device, which serves for a quick and easy checking of the weighing accuracy.

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• versatile in use

• minimal maintenance works

Requirement

• straight section in the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Chemistry

-

Coal

-

Waste industry

-

Plastics

-

Food

-

Animal feed

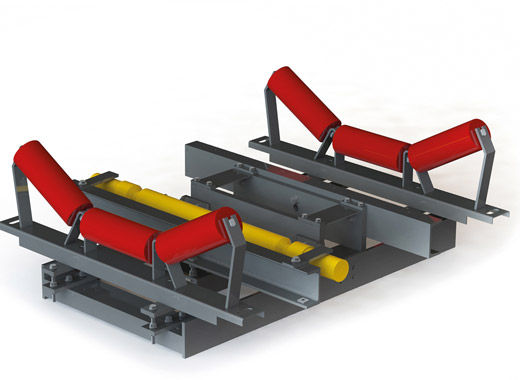

Multiple Roller Belt Scale EBW-M-C2

for installation into existing conveying belt systems

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 1 t/h – 10000 t/h

Belt speed: 0,1 m/s – 3 m/s

Belt width: 300 mm – 2800 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to coarse-grained

Inclination conveyor belt: up to 20 degrees increasing or decreasing

ATEX: versions available

Accuracy: ± 0,5 %

If required customized special solutions are available!

Multiple roller belt scales of the series EBW-M-C2 are suitable for installation into existing conveying belt systems. Their main application is measuring and totalizing of bulk material flow. For the weight measuring two modified roller stations are mounted onto the scale. The multiple roller belt scale is applied for very high accuracy requirements and if the belt speed is very high.

For the speed measuring a digital tacho is provided which is either running on the return belt or attached to the tail pulley. Optionally the scale can be equipped with a test weight device, which serves for a quick and easy checking of the weighing accuracy.

Legal for trade versions are available (MID)!

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• versatile in use

• minimal maintenance works

• heavy duty design

Requirement

• straight section at the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Chemistry

-

Coal

-

Waste industry

-

Plastics

-

Food

-

Animal feed

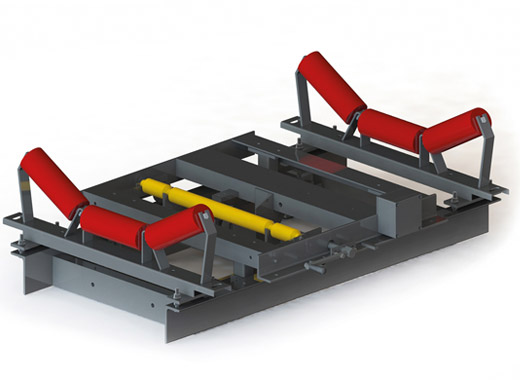

Multiple Roller Belt Scale EBW-M2

for installation into existing conveying belt systems

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 1 t/h – 10000 t/h

Belt speed: 0,1 m/s – 3 m/s

Belt width: 300 mm – 2800 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to coarse-grained

Inclination conveyor belt: up to 20 degrees increasing or decreasing

ATEX: versions available

Accuracy: ± 0,25 – 0,50 %

If required customized special solutions are available!

Multiple roller belt scales of the series EBW-M2 are suitable for installation into existing conveyor belt systems. They are used for measuring and totalizing of bulk material flow. For the weight measuring two modified roller stations are mounted onto the belt scale. The transmission of the load to the load cell is done by a leverage. By that very stable conditions are created. The multiple roller belt scale is applied for very high accuracy requirements and if the belt speed is very high.

For the speed measuring a digital tacho is provided which is either running on the return belt or attached to the tail pulley.

Optionally the scale can be equipped with a test weight device, which serves for a quick and easy checking of the weighing accuracy.

Legal for trade versions are available (MID)

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• versatile in use

• minimal maintenance works

• heavy duty design

Requirement

• straight section at the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Chemistry

-

Coal

-

Waste industry

-

Plastics

-

Food

-

Animal feed

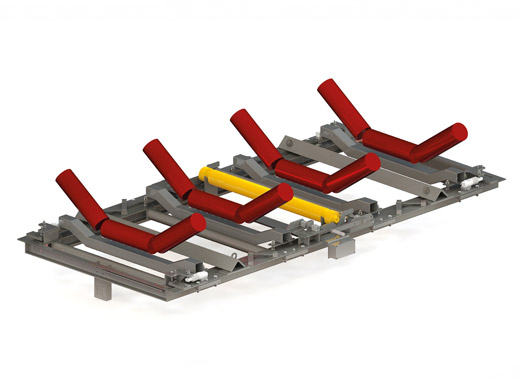

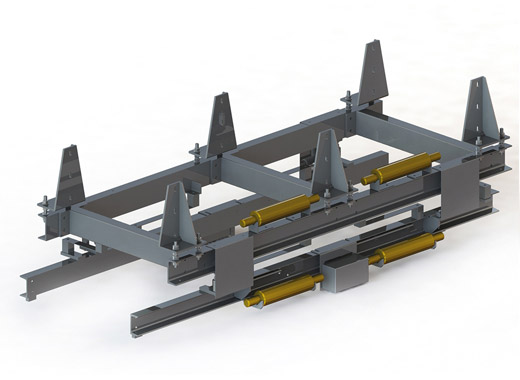

Multiple Roller Belt Scale EBW-M4 (M3)

for installation into existing conveying belt systems

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 1 t/h – 10000 t/h

Belt speed: 0,1 m/s – 5 m/s

Belt width: 300 mm – 2800 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to coarse-grained

Inclination conveyor belt: up to 20 degrees increasing or decreasing

ATEX: versions available

Accuracy: ± 0,125 % – ± 0,5 %

If required customized special solutions are available!

Scales of the series EBW-M4 (M3) are suitable for installation into existing conveying belt systems. They are used for measuring and totalizing of bulk material flow. The multiple roller belt scale is applied for very high accuracy requirements and if the belt speed is very high. The transmission of the load to the load cell will be conducted by leverage or the weighing bridge is mounted on several load cells. For the speed measuring a digital tacho is provided which is either running on the return belt or attached to the tail pulley.

Optionally the scale can be equipped with a test weight device, which serves for a quick and easy checking of the weighing accuracy.

Legal for trade versions are available (MID)!

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• versatile in use

• minimal maintenance works

• heavy duty design

Requirement

• straight section at the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Chemistry

-

Coal

-

Waste industry

-

Plastics

-

Food

-

Animal feed

Pipe-Conveyor Scale EBW-M-R-Ø

for installation into existing pipe conveying belt systems, Innovation by KUKLA

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 10 t/h – 3000 t/h

Belt speed: 0,5 m/s – 5 m/s

Pipe diameter: 200 mm – 500 mm

Bulk density: 100 kg/m³ – 4000 kg/m³

Granulation: dusty to coarse-grained

Inclination conveyor belt: up to 20 degrees increasing or decreasing

ATEX: versions available

Accuracy: ± 1,0 – 3,0 %

If required customized special solutions are available!

Multiple roller belt scales of the series EBW-M-R-ø are constructed specifically for an installation into existing „pipe conveyors“. The modified roller stations are beared over a roller station bridge onto the load cells, therefore this type of scale can also archieve a high precision. They are used for measuring and totalizing of bulk material flow. For the speed measuring a digital tacho is provided which is either running on the return belt or attached to the tail pulley.

Optionally the scale can be equipped with a test weight device, which serves for a quick and easy checking of the weighing accuracy.

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• versatile in use

• minimal maintenance works

• heavy duty design

Requirement

• straight section at the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Chemistry

-

Coal

-

Waste industry

-

Plastics

Built-in Belt Scale for Apron Conveyors EBW-P

a particularity among Built-In Scales

Technical Data:

Conveying material: Bulk materials

Conveying capacity: 5 t/h – 500 t/h

Belt speed: 0,1 m/s – 1 m/s

Belt width: 400 mm – 1400 mm

Bulk density: 500 kg/m³ – 4000 kg/m³

Granulation: fine grained to coarse-grained

Inclination conveyor belt: up to 40 degrees increasing or decreasing

ATEX: versions available

Temperature: up to 600° C

Accuracy: ± 1,0 – 3,0 %

If required customized special solutions are available!

The built-in belt scale is integrated into an existing apron conveyor. It is mainly used to measure the clinker production directly after the kiln. The rail system where the single plates are moved by wheels is fixed on the KUKLA-scale. Because of the stable construction, it is possible to install the belt scale for apron conveyors in plate conveyors of up to 40 degrees inclination. Suitable for materials with high temperatures.

Significant Benefits

• easy construction

• easy installation in existing systems

• test weight for an easy and quick check of the weighing accuracy

• for high temperature range

• minimal maintenance works

• heavy duty design

Requirement

• straight section in the area of the scale

• appropriate setting distance after material transfer

Application Range:

-

Construction material and minerals

-

Gypsum

-

Cement

-

Steel

-

Coal